“Vicky” as my little S1 135 is known, was gently upgraded over the first few years. The track day bug eventually bit hard and around 2008 the upgrades began to pick up a pace. We were offered a chance to run at Kames motorsport venue. After some discussions with the very welcoming group that ran the venue I decided to try my hand at the 2009 Scottish Sprint Championship. This is when things started to get a little silly.

The car ended up with an impressive specification.

204 bhp with many torques. Steel rods, baffled sump etc…

Emerald and throttle bodies

2Bular exhaust and manifold. Custom built to my engine spec designed by Jim Valentine using some pretty fancy software. 1 3/4” bore.

Custom maps with launch control (of a fashion) and full throttle shift

Custom valved Nitron dampers , 750lb front / 1000lb rear with helper springs, larger anti roll bar

Khumho V70 tyres with tire pressure monitoring

AP racing brakes with Carbon Lorainne pads.

Full race seat and harnesses

GPS data logging and the largest rear diffuser I have ever seen on an S1.

Needless to say it was a pretty potent machine that always inspired confidence in the corners and on the brakes. I never did manage a complete clean lap at knockhill, however a composite time from the three best sector times would put it on a 53 -54 second lap (Racelogic GPS). I don't know if this is considered to be a decent time now with all the new V6 cars out there but I was happy with it at the time.

So what happened?

Well the race engine detonated itself when I spun up the rear wheels pulling out of a lay-by that had gravel on the exit route. It turns out the engine had oil starvation damage probably caused by the time I chopped through an oil cooler pipe at Knockhill. Kerbs are there to be driven over, didn't expect it to pinch a hose between the chassis and the under tray though.

Temporary replacement engine was to be built to a budget to get me to the end of the year. We took a VVC engine, fitted a custom made exhaust cam and bolted on all the good bits. It gave out 187 Bhp but never felt as strong as the 8500rpm screamer it replaced. This was probably the first stage of me falling out of love with the car. It just felt slow. Changes to my rota at work meant I couldn't compete in the last couple of rounds so that was the end of my racing for that year.

Over all a pretty good year racing. I managed a couple of class wins, mostly finishing 2nd or 3rd behind the Scottish champion Graham Bremner in his 300 Bhp Turbocharged Exige. The highlight of the year was being invited to drive Mike’s Stouts Elise at Boyndie. Came within 0.5 secs of the class record that weekend. If I had managed to keep up the same rate of points scoring till the end of the year I was comfortably in the running for top rookie. Unfortunately work got in the way and ruined it. So getting ready for 2010 season I am informed that there has been a rule change to state that cars may only run in my class if they are fitted with the original style of cylinder head that the came out of the factory with. As my car now had a VVC engine it was no longer eligible. Funny how the rule just appeared. Feel a little bitter about that. The proposer was my main rival Graham Bremner. Lesson learned, don't post anything about what you are doing to your car on a club forum.

So Racing over and done with I decided to move on from the Elise and started looking at an Evora. The plan was to hand the car to Dan Jude who would take off all the race car parts and return the car to standard in a condition that it could be sold. This was agreed at the start 2010. The deal being the sale of the race car parts would cover the cost of the restoration. The car was to get new front and rear clams, full respray and a stock 135 spec engine put back in. I never expected this process to be a quick turn around, maybe 3-4 months at most.

So after years of avoidance and being uncontactable, being told that the bodywork was not in the same place, being lied to, the story changing every call., the engine was not fitted, couldn't source parts. X,Y and Z reasons for it not being done. It came to a head when he starting to complain on this forum that after four years of having the car it was starting to cost him money… he suggested the deal and when it was his turn to deliver he basically didn't. I eventually manage to get him to agree to return the car in whatever condition it is in. So several thousands of pounds worth of upgrades in his pocket and a box of bits delivered back to my door.

No exhaust came back with the car..

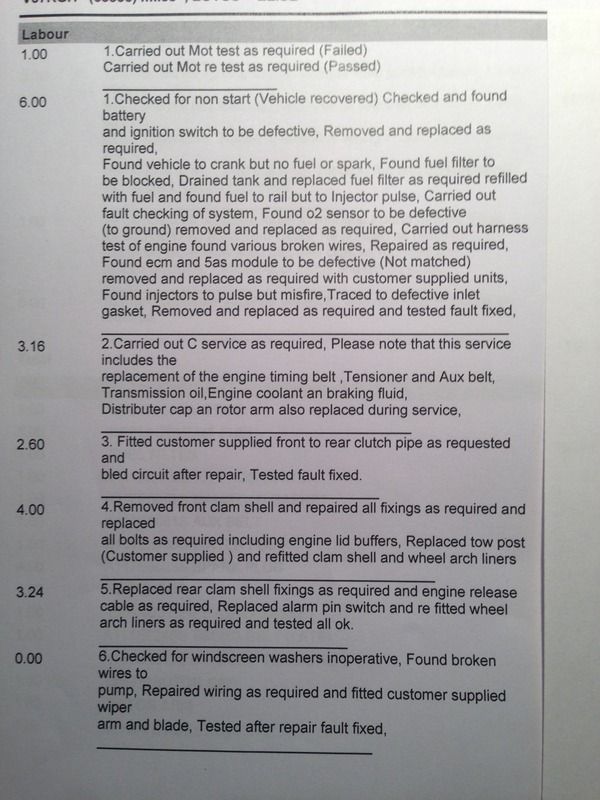

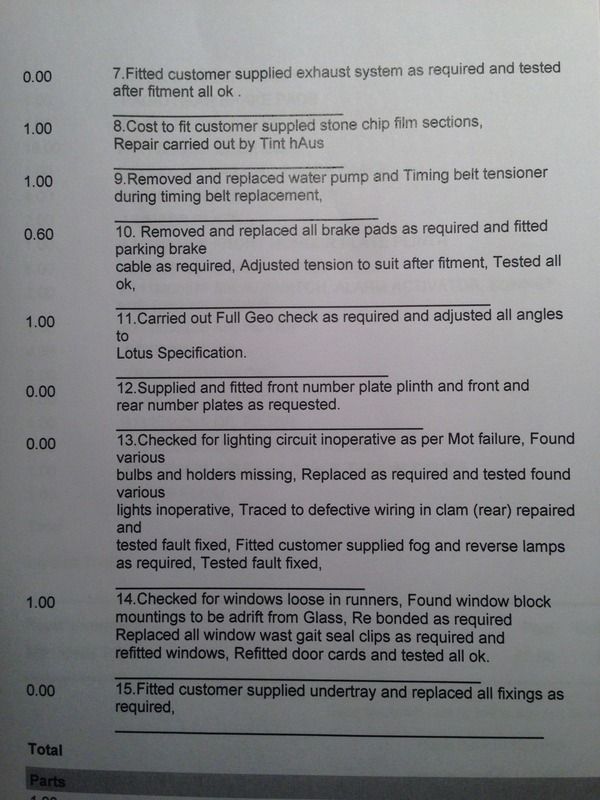

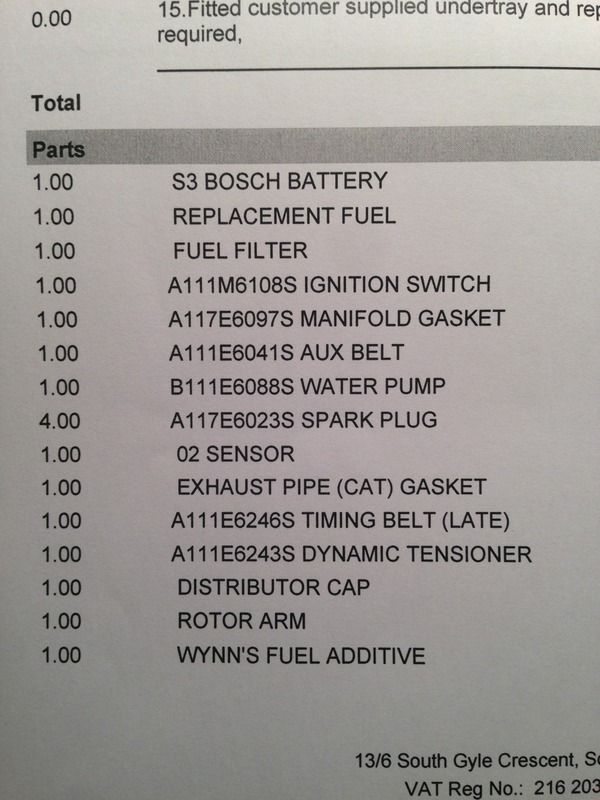

I have been reluctant to post what was wrong and unfinished with the car as it would be my word against his. I now have a list from a well respected independent individual listing everything that had to be done just to get it running again.

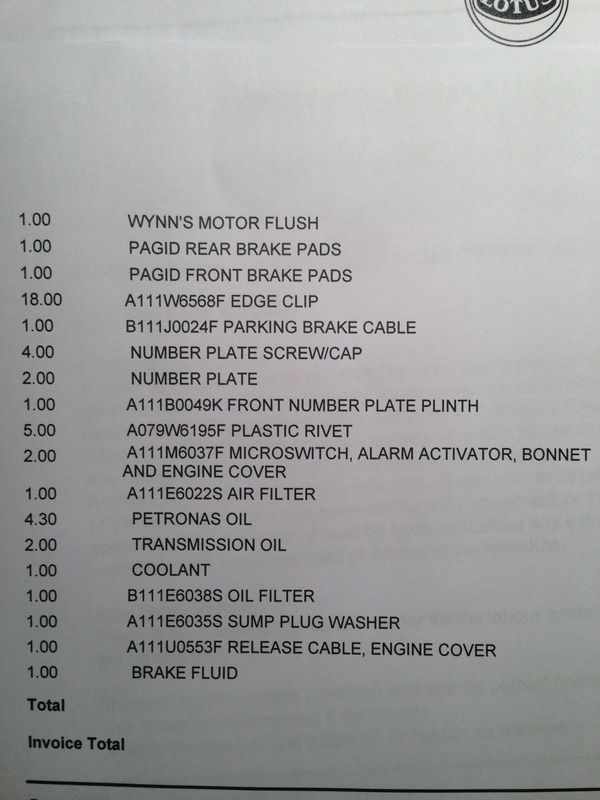

IMAGE WORK SHEET FROM CRAIG

So Craig and his team had the car for just over a month. I am almost lost for words to describe the transformation. The level of professionalism is second to none. So now for some happiness. The resurrection and the return

Craig and his team had to rectify so many faults and rework so much of what had been attempted by Dan that the number of hours actually spent on the car to get it back to the condition it is in now is staggering. Just look through the work sheet below and you will get an idea of how far away the car was from being ready to run. It is important for me to post this as it is no longer my word against Dan's regarding the condition that I received the car back. Independant honest professional accounting of the work carried out.

So all done and dusted, through the MOT and wheels refurbished to boot. Throughout the whole process Craig has been contactable pretty much day and night, Estimates were provided and the cost at the end was spot on to the estimate, the only extras being what I asked for. I must also say the SE generosity and love was in attendance with parts being offered at very reasonable cost to help me on my way. All in it obviously cost more than a few pennies, I can honestly say his rates were exceptionally fair and the work was top class. It is all in the details. He has a high standard that he expects from his team. The workshop is imaculate which in my experience lends itself to promoting a high degree of professionalism. You just won't get work done to this standard in a workshop with sh*t stacked all over the place.

People keep asking me if I’m back, and I haven't really had an answer, but now yea I’m thinking I’m Back.