Here is another shot of the sping on the end

- why did this happen? because they are made of a totally inappropriate steel for the use to which they are put... standard shaved wire, same as used by OEs in low lift shopping trolly engines

high lift long duration cams MUST have race wire springs, all my engines now have bespoke Kobi race wire springs after this experience....

The story behind this was ;-

this was from Sean Bicknell's 2006 Lot engine, he won his class outright first race, then had a fault which he first blamed on the gearbox {?} then the paddleshift [?] but turned out to be his electrical cut off rotting [he lost all electrical power half way through the race] ......it was something of a sign of things to come,

whilst he was searching for his problem, I suggested fitting a proper clutch since the engine was a rapid chuck together and originally had simply an uprated pressed steel clutch.....which broke testing as they so often do, no doubt not helped by Sean's flat shift paddle clutch, so I suggested an engine out since the crankset would need to be re-balanced., which Sean paid for and a second very expensive Quatermaster clutch as spare [completely unnecessary, but his faith in clutches must have been shattered somewhat by the wretched pressed steel cover disintegrating]

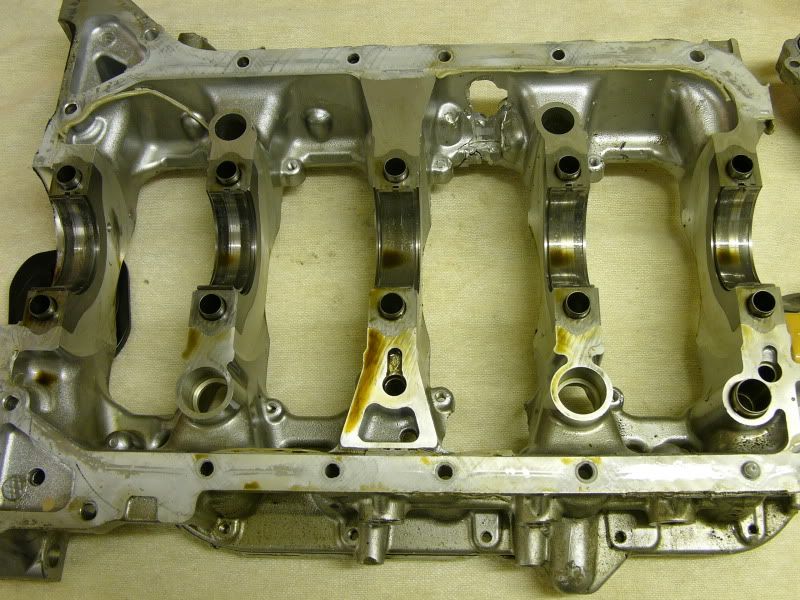

I used the opportunity to check the whole engine, there were some bore issues from not running in under load, so liners were replaced FOC and I then rebalanced the crankset to a new flywheel and Quatermaster twin plate clutch to 24gmm [inside 2004 Mclaren F1 tolerence].

I thought I'd decoke the head, and bear in mind there had been no apparent running issues with the engine till that point, only to find one spring collapsed and broken -with as I said next to no use....the spring had simply collapsed onto itself and gone to a higher rate, but would have trashed the valve and the spring seat given time. I sent the springs back to the supplier who kindly supplied a complete set FOC, so Sean's engine was rapidly rebuilt and went off again, but asked for an explanation as to why this happened.......nothing came back by way of analysis, I waited months, the man who I delt with at said company eventually left, but no explanation. So in sheer frustration I started phoning around all the spring manufacturers [very specialist] who made them for said 'manufacturer of cams and verniers etc' - they in fact subcontracted the manufacture of the springs. Eventually I found the spring maker to this company, Performance Springs, who manufacture on a very large scale for lots of end users including OE's. I asked them if they had had back a double spring that had broken about a year earlier for technical analysis..... no they had not. Astonished I sent in another from the set that had been in Sean's engine and they duly identified it as theirs and that it had been supplied to known end user. So could they give me an analysis, not of failed spring since I no longer had it, but of that springs material specification. I was told it was standard shaved wire .... cheap one up from cheapest spec [non shaved] commonly used by OEs for shopping trolly engines.......I was amazed, so I asked whether they could give me a fatigue life given a 274deg 12.2 mm lift spring, - their immediate reaction, this spring SHOULD NOT be used with such a cam, - please can you work out a fatigue life. They came back the next day and said..... 48hours max.......that is to say that after 48hours running this spring would have fatigued outside perameters suitable to control the valve on a 12.2mm lift cam.

I have one word for such as this......madness

no two and profiteering...