Fergus organised a day there a while ago, probably quite soon after they started out, and believed they had a good set up and reliable RR calibration etc. It's actually a 4x4 rolling road, so popular with the Jap importers obviously.

So decided to use them for Before and After runs during some minor mods which Robin is helping me to do.

My S1 has been essentially standard since the word go in 1999, and sports only:

- K&N replacement panel filter

- Stainless sports exhaust (Motobuild supplied)

- Trophy 160 52mm alu Throttle Body

- Cat still in place, albeit original so probably a bit lighter now!

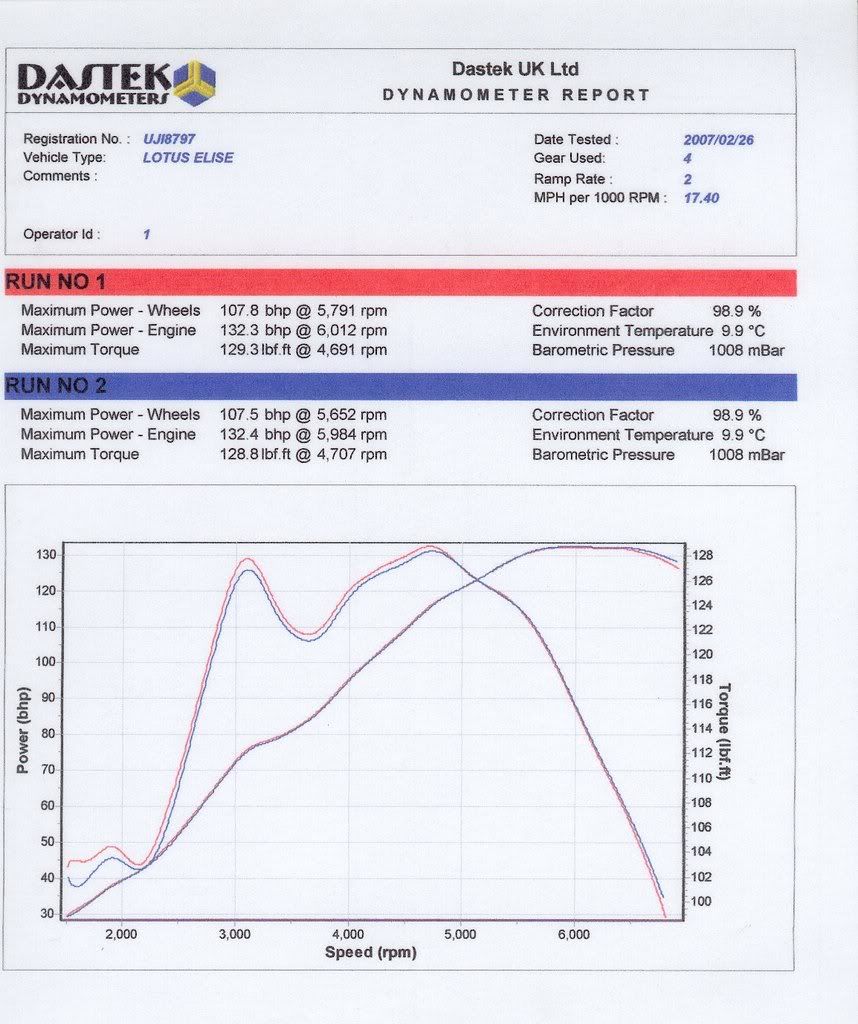

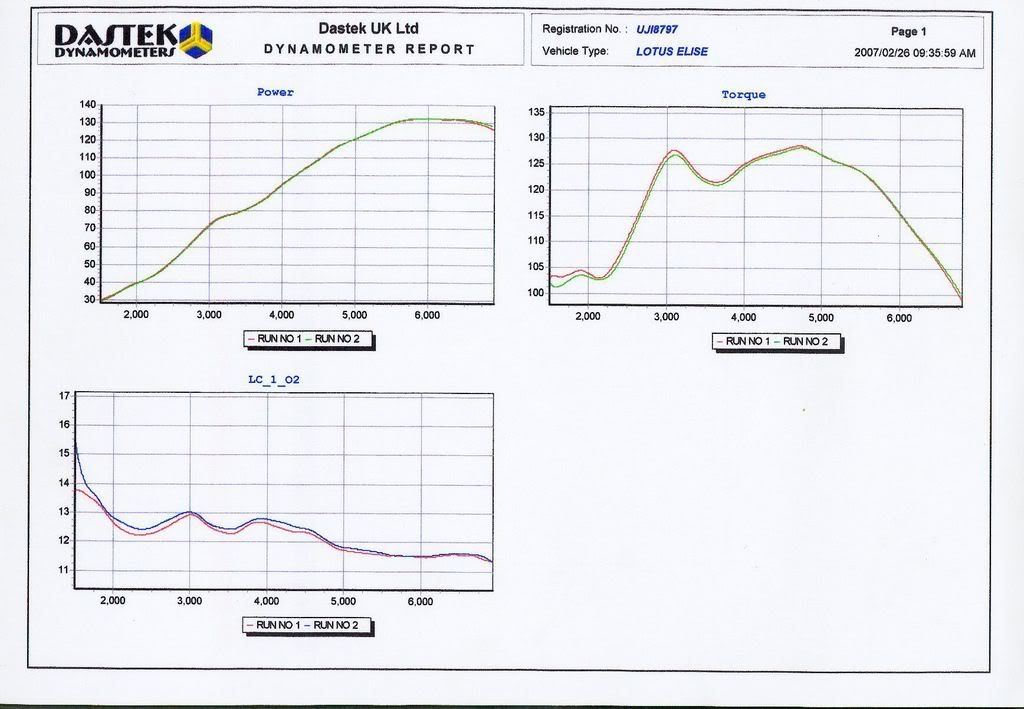

2 full power runs completed, revealing...

- 132bhp at flywheel (107 at the wheels)

- 129 lbft (175Nm) torque

- Peak power at 6000rpm

- Peak torque between 3100 and 4900 rpm

- Decent path of air-fuel mixture across rev range

- Minor spike in mixture richness at 3500rpm - with similar 5 lbft loss in torque

- 118bhp

- 122 lbft (165Nm) torque

- Peak power at 5500rpm

Dastek are keen to sell their "Unichip" interceptor ECU device, however until Jedi Master Robin has been convinced of its integrity, I am not the least bit interested. These results show the MEMS is just fine for standardish cars, and we will see how it can perform once my upgrade is complete. Robin's runs showed strong results from his latest upgrade, though, however failings might be being uncovered with the Lotus K4 chip for running modded cars...but I'll let him tell you about all that!

£47 for the session, took best part of an hour per car. Plus some blethering in between obviously. For H&S reasons, Dastek are not mad keen on you viewing the whole affair, but once set up and safe, they will allow one visitor to the test cell for one of the runs if you ask.