OK,

Well it's time to go back to basics I think and do some conclusive tests to be sure we know what *is* happening.

(1) We know there is spark because you've run it with a loose plug in number 1 lead?

If not then we need to do this and I would do it with all leads and someone else observing. Now it is my belief that the ECU cannot run the ignition without seeing the correct crank position sensor pattern, so that should rule out CPS failure.

(2) We know there is fuel circulating because you've removed the return side and run it through a long hose into a bucket or can?

If not then I suggest you do that (without cranking - just the first few seconds of priming should be enough to demonstrate that the fuel pump and circuit is game).

If that's OK, run a longer test - keep cranking (you can remove spark plugs to reduce load on starter motor) and see whether the fuel return dries up after a while. This could be the case if you had a corroded connector in the engine harness connector blocks en route to the fuel pump. When cold it might allow enough current to prime the motor, but on continuous running the connector will heat up (there's a lot of current flowing and even a 1 ohm resistance will generate significant heat) and this heat causes the resistance to increase - vicious circle time until too much voltage is lost across the bad connection and the pump stalls. Leave it for a while to cool down and it starts to work again.

So if on average it runs for 20 seconds after catching, try cranking for a 30 seconds and make sure fuel is returned at full flow for that whole time.

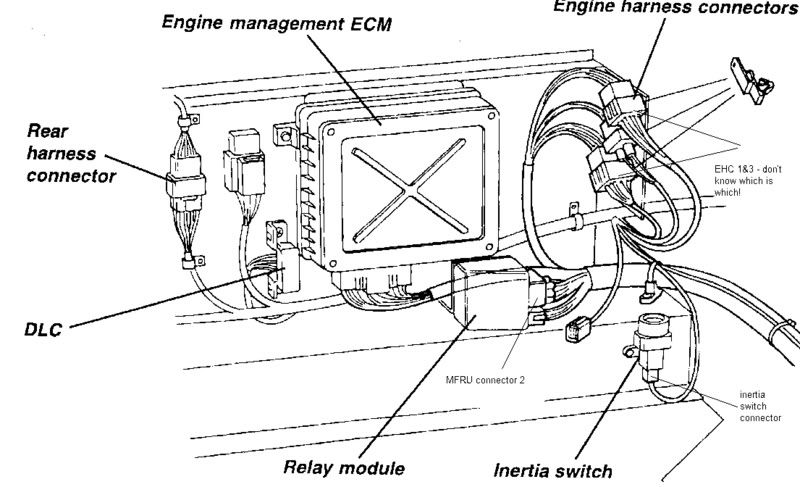

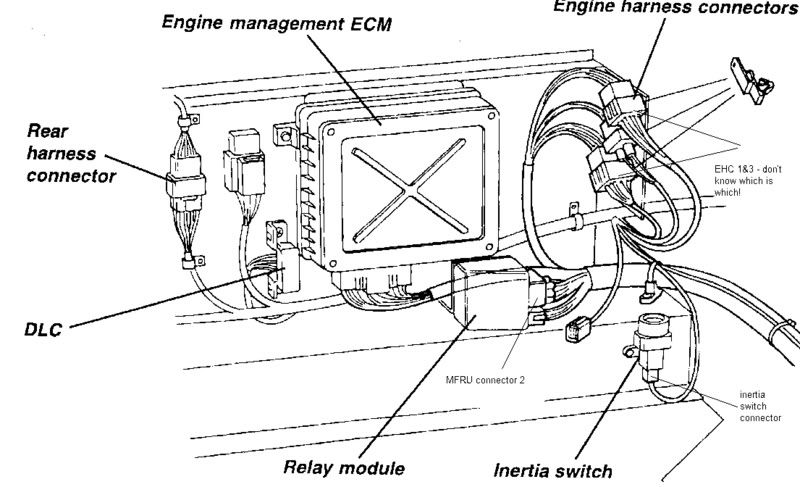

I would disconnect each of the harness connectors anyway for a visual inspection - you need to track them all down - for the fuel pump there are :

Fuel Tank Harness Connector - I think this has four wires total - the two wires you care about are Black (ground) and Brown/Grey (live). I think this is the plug on top of the fuel pump under the access hatch behind the pax seat - good luck with that one!

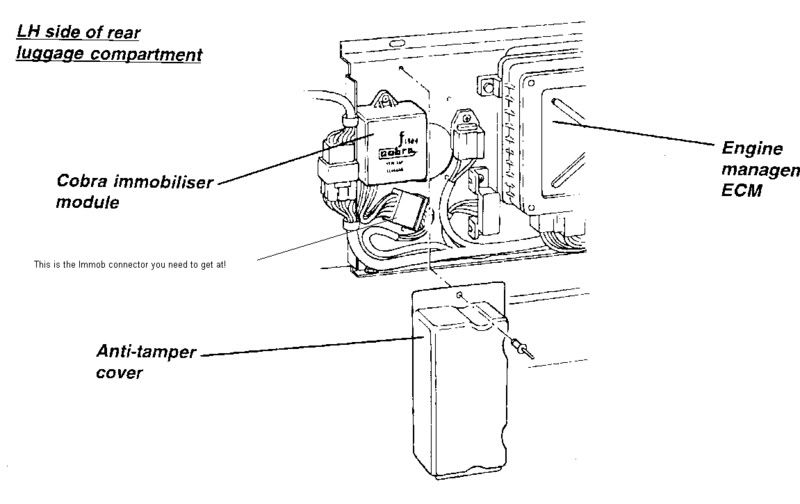

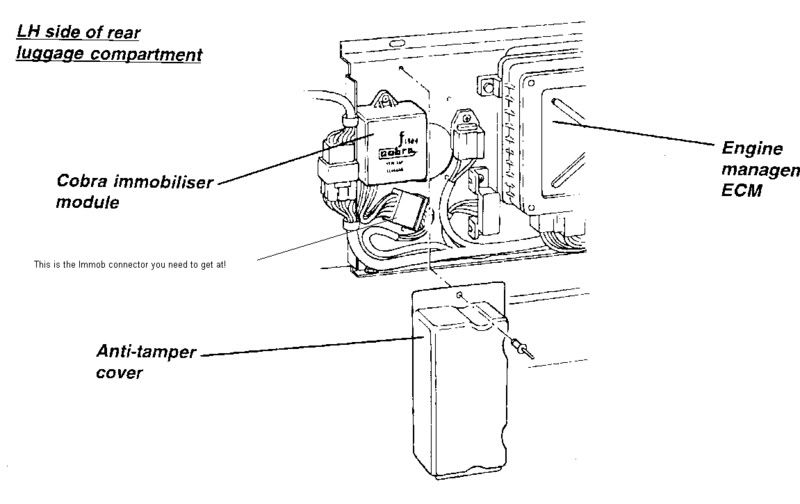

Immob connector - need to drill off the rivets on security cover on the immob unit to access this one. The wire in and out of this will still be Brown/Grey.

Engine Harness Connector 1, pin 4. Still Brown/Grey.

Bottom of MFRU, connector 2, pin 1, Brown/Grey and connector 2, pin 4, White/Purple.

Engine Harness Connector 3, pin 2, White/Purple on both sides.

Inertia switch connector, White/Purple on one side, Purple on the fused live side.

10A fuse (number 17?) in the fuse panel.

Here are the harness locations if of use (your actual ECU might not be in the boot, depending on age of car, but harness positions move with the ECU).

(3) I assume it's not now backfiring (i.e. there's no way you've fixed the fuelling problem and introduced a firing order problem in the process).

(4) Although it's a no-no in normal running, have you tried to start the car on part throttle? I assume it will just splutter and die as before. I would also disconnect the TPS wiring and run it without a TPS (the ECU doesn't need the TPS to work and will just ignore it if not present). Opening the throttle manually will bypass any problem with the IACV not opening.

(5) Given it's now quite cold if the problem is that the coolant temperature sensor or inlet air temperature sensors are gubbed, it could make a significant difference. Disconnect the brown sensor at the water elbow and the green one on the intake manifold.

(6) Now that you have a spare fuel rail you could consider running your original fuel rail loose into a bed of paper towels and see just how much fuel gets squirted into it when cranking. Note that the ECU doesn't do fuelling in an obvious way on cranking - rather it just squirts now and then to avoid flooding the engine, so provided you get some fuel into the towels, I think you can be happy.

I'm guessing you can rule some of the above out because of other tests you've done already ... but worth thinking about it all again.

Cheers,

Robin