Why I don't like [what gets done to] the Rover K series and

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

Lesser issues also -

are the crank carrier to block has just two dowels, it needs all ten

the oil rail that anchors the longbolts is insufficiently stiff and has too small a foot print

the block is open decked, like all the engines that have copied K [ including Honda K20] which has longevity and heat transfer issues.

the sump is no longer baffled, unlike the initial production Ks

there is a crank resonance issue at 7000 rpm which is widely misunderstood.

Having said that, all the issues in this and my previous posts on this thread can be overcome, and my engines after a lot of research have remedies -

are the crank carrier to block has just two dowels, it needs all ten

the oil rail that anchors the longbolts is insufficiently stiff and has too small a foot print

the block is open decked, like all the engines that have copied K [ including Honda K20] which has longevity and heat transfer issues.

the sump is no longer baffled, unlike the initial production Ks

there is a crank resonance issue at 7000 rpm which is widely misunderstood.

Having said that, all the issues in this and my previous posts on this thread can be overcome, and my engines after a lot of research have remedies -

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

So what is the biggest problem with the Rover K series engine? Clearly there are some problems around the basic 120/160BHP versions, and sufficient to cause many owners intense frustration - the ever present possibility, I would say inevitability of so called "HGF" because it is not the gasket that fails. But this issue is understood sufficiently well measures to alleviate the problem, and I have I believe managed to modify the cause of the problem such as to eliminate it all together by means of a significantly improved water pump, and radical water management modifications inside the block, - at any rate there are clearly defined remedies openly available now to rebuild engines that encounter this problem, even if there are not enough accurate digital, properly calibrated hardness testers available to test the condition of any cylinder head that might be reused.

Despite this people still look for alternatives, and many of those in the business of supplying alternative engines continue to insist that the engine is a grenade waiting to explode as soon as it is tuned.

There is the problem, the biggest problem with this engine, it has to be tuned to give the power that many want -

- Should that be a problem? Absolutely not, all engines get tuned, - is the Honda K20A2 fit in OE form to race in BTCC, no, it gets tuned extensively, so do the Vauxhalls, and the BMWs, and the SEATs etc etc...... do they all grenade............ occasionally, but by enlarge no, no more than stock Honda K20s [of which I have 5 out of Elise's that have thrown rods].

So why is this? - well by enlarge the BTCC teams will use highly competent engine builders to do the work, that doesn't mean those builders never have anything to learn [we all should be open to that, and certainly my current understanding of the K series is the result of 5 years hard work] or sometimes get it wrong, but it has to be said that the vast majority of the catastrophic failures that this engine suffers is down to totally careless incompetent or botched engine building done by people tuning it for more power.

Despite this people still look for alternatives, and many of those in the business of supplying alternative engines continue to insist that the engine is a grenade waiting to explode as soon as it is tuned.

There is the problem, the biggest problem with this engine, it has to be tuned to give the power that many want -

- Should that be a problem? Absolutely not, all engines get tuned, - is the Honda K20A2 fit in OE form to race in BTCC, no, it gets tuned extensively, so do the Vauxhalls, and the BMWs, and the SEATs etc etc...... do they all grenade............ occasionally, but by enlarge no, no more than stock Honda K20s [of which I have 5 out of Elise's that have thrown rods].

So why is this? - well by enlarge the BTCC teams will use highly competent engine builders to do the work, that doesn't mean those builders never have anything to learn [we all should be open to that, and certainly my current understanding of the K series is the result of 5 years hard work] or sometimes get it wrong, but it has to be said that the vast majority of the catastrophic failures that this engine suffers is down to totally careless incompetent or botched engine building done by people tuning it for more power.

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

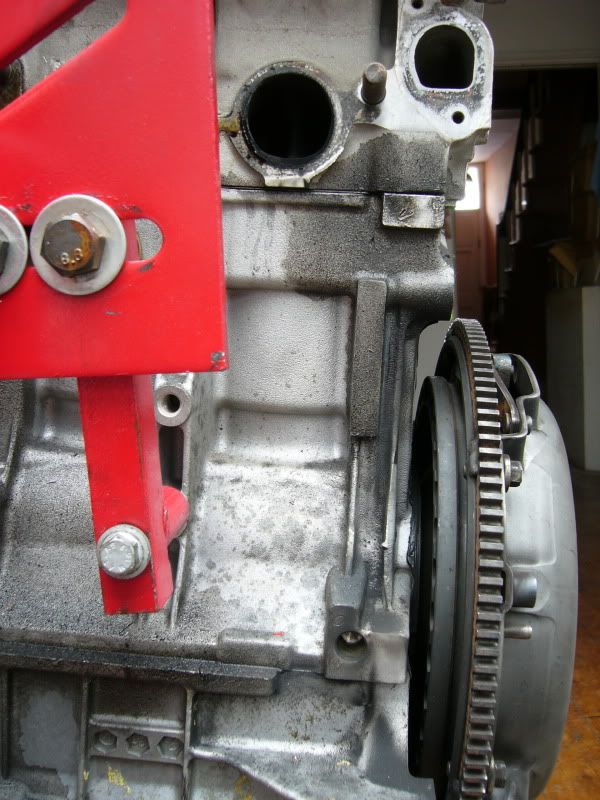

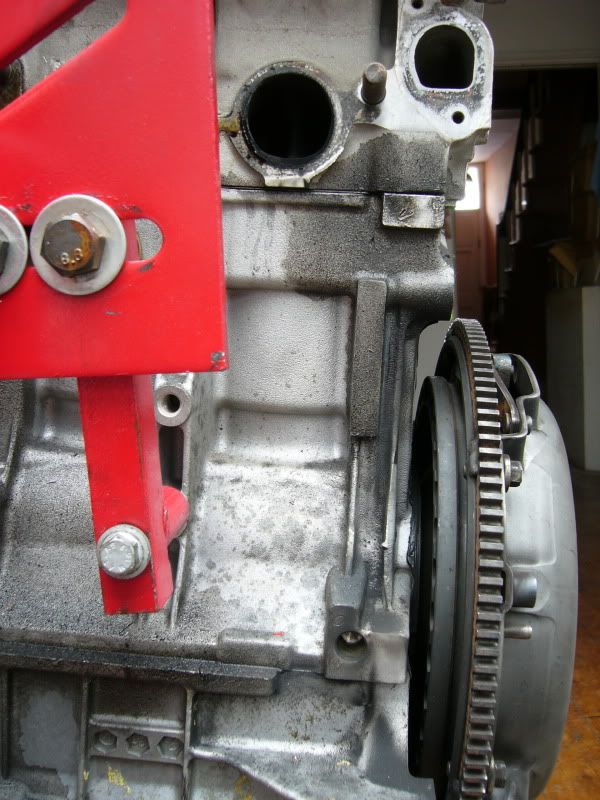

Examples -

- below is a very expensive short end built but a "professional" who considered cracking liners were caused by the open topped block. In fact liners crack because the same company had continued to use the old plastic dowels, so apart from the misguided diagnosis these people decided to close the top of the block [not a bad idea in itself - that will have several advantages] by welding it up and re-machining it.

- There lies the problem, they were careless/ill informed/just didn't care to study the engine, enough to not realise that the K unlike all other production I4s is as light as it is BECAUSE of the use of a heat treated alloy LM25, and therefore by heating it enough to weld in the inserts the very remedy they were using was destroying the treated state of the block and rendering it scrap

On this newly rebuilt short end the builder's welding had reduced the hardness of the block from 120 brinnel to 42

Unknowing incompetence....

- below is a very expensive short end built but a "professional" who considered cracking liners were caused by the open topped block. In fact liners crack because the same company had continued to use the old plastic dowels, so apart from the misguided diagnosis these people decided to close the top of the block [not a bad idea in itself - that will have several advantages] by welding it up and re-machining it.

- There lies the problem, they were careless/ill informed/just didn't care to study the engine, enough to not realise that the K unlike all other production I4s is as light as it is BECAUSE of the use of a heat treated alloy LM25, and therefore by heating it enough to weld in the inserts the very remedy they were using was destroying the treated state of the block and rendering it scrap

On this newly rebuilt short end the builder's welding had reduced the hardness of the block from 120 brinnel to 42

Unknowing incompetence....

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

And apart from rendering the block unsound, the metal becomes soft so the compression trim at the rear of the gasket digs into the soft metal, which causes the gasket to leak oil and water, you can always tell one of theses 'EVO4' blocks from the oil stain at either end of the engine...... an engine scrapped by the very process of modifying it... stupid, and inevitable.

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

Then there is this problem, that associated with the modifier of the welded blocks but also their cheaper open topped block -

they use a torque plate to hot hone the bores, brilliant really good practice, I do to all my engines, it is of significant benefit to bore seal, oil consumption, piston wear, torque and engine life.

BUT the whole point is to mimick the conditions that the block and individual bores are under when the head is torqued up. So a torque plate is used, this is a simple steel plate that fits over the block dowels and is then torqued using the same torque and bolt as in the final build, or if oe bolts 2 new sets. The torque plate must have the same stiffness as the 3mm thin walled 100mm talk aluminium head. What does this company do, they use a 100mm tall solid cast iron plate, with 100mm grade 10.9 bolts torqued to 60lbft, then sell them out to the tuners...... who use in ever case I have had one of these horrors come my way stock OE bolts that is 9mm grade 8 bolts torqued to 20Nm +180+180 = approx 35-40lbft.

It is difficult to imagine a more dim-witted, thoughtless incompetent thing to do to an engine, it is bad practice gone stratospheric

the result is -

and

they use a torque plate to hot hone the bores, brilliant really good practice, I do to all my engines, it is of significant benefit to bore seal, oil consumption, piston wear, torque and engine life.

BUT the whole point is to mimick the conditions that the block and individual bores are under when the head is torqued up. So a torque plate is used, this is a simple steel plate that fits over the block dowels and is then torqued using the same torque and bolt as in the final build, or if oe bolts 2 new sets. The torque plate must have the same stiffness as the 3mm thin walled 100mm talk aluminium head. What does this company do, they use a 100mm tall solid cast iron plate, with 100mm grade 10.9 bolts torqued to 60lbft, then sell them out to the tuners...... who use in ever case I have had one of these horrors come my way stock OE bolts that is 9mm grade 8 bolts torqued to 20Nm +180+180 = approx 35-40lbft.

It is difficult to imagine a more dim-witted, thoughtless incompetent thing to do to an engine, it is bad practice gone stratospheric

the result is -

and

Re: Why I don't like [what gets done to] the Rover K series

To clarify my understanding: you bolt that that thick plate down to reproduce the exact conditions of the engine in service then hone like that? Do you put a head gasket in as well or is that unessesary?

1994 Lotus Esprit S4 - Work in progress

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

Rich H wrote:To clarify my understanding: you bolt that that thick plate down to reproduce the exact conditions of the engine in service then hone like that? Do you put a head gasket in as well or is that unessesary?

Yes head gasket in place, then run water through at 74 deg C.

Re: Why I don't like [what gets done to] the Rover K series

I take your point, but the pics are rather meaningless without being able to see that the vernier hasn't moved?

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

woody wrote:I take your point, but the pics are rather meaningless without being able to see that the vernier hasn't moved?

If you want to come over I'll set one of these blocks up and you can measure it for yourself -

but try thinking like this;-

the WHOLE point of torque plate honing is to mimic as near as possible running conditions - so what sort of logic defying, stratospherically stupid thinking bolts a 100mm thick iron plate to mimic the stock ally 3mm thick cylinder head and 10mm 10.9 bolts at 60lbft rather than OE at Stock torque setting

it cannot possibly work - in fact that bore is one of the best, they vary on each engine and I have seen 22thou out of round

IT IS JUST MINDBOGGLING INCOMPETENT ENGINEERING, -in fact it is not engineering at all it is butchery - !

Re: Why I don't like [what gets done to] the Rover K series

I'm surprised it moves so much!

If the block is 'relaxed' how does that change things? ie would they haev been better off not bothering?

If the block is 'relaxed' how does that change things? ie would they haev been better off not bothering?

1994 Lotus Esprit S4 - Work in progress

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

-

KingK_series

- Posts: 567

- Joined: Tue Jan 05, 2010 10:10 am

Re: Why I don't like [what gets done to] the Rover K series

It is normal on all engines - even great big cast iron lumpsRich H wrote:I'm surprised it moves so much!

If the block is 'relaxed' how does that change things? ie would they haev been better off not bothering?

- get a boot on American V8 blueprinting and see them use the same technique [intelligently] on NASCAR V8 engines.

Re: Why I don't like [what gets done to] the Rover K series

Makes sense just didn't expect it to be as significant!

1994 Lotus Esprit S4 - Work in progress

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

1980 Porsche 924 Turbo - Funky Interior Spec

2004 Smart Roadster Coupe - Hers

Re: Why I don't like [what gets done to] the Rover K series

I fully agree.KingK_series wrote:woody wrote:I take your point, but the pics are rather meaningless without being able to see that the vernier hasn't moved?

If you want to come over I'll set one of these blocks up and you can measure it for yourself -

but try thinking like this;-

the WHOLE point of torque plate honing is to mimic as near as possible running conditions - so what sort of logic defying, stratospherically stupid thinking bolts a 100mm thick iron plate to mimic the stock ally 3mm thick cylinder head and 10mm 10.9 bolts at 60lbft rather than OE at Stock torque setting

it cannot possibly work - in fact that bore is one of the best, they vary on each engine and I have seen 22thou out of round

IT IS JUST MINDBOGGLING INCOMPETENT ENGINEERING, -in fact it is not engineering at all it is butchery - !

Just qustioning the validity of the pics? If I pitched that I'd be shot to bits.

Still genuinely interested in what you're doing.

Re: Why I don't like [what gets done to] the Rover K series

To clarify, woody is an aerospace engineer and his day job includes that sort of picture of engineering issues - he's trying to help you put you point across clearer for everyone, Simon, not questioning it.

2010 Honda VFR1200F

1990 Honda VFR400 NC30

2000 Honda VTR1000 SP1

2000 Kawasaki ZX-7R

1990 Honda VFR400 NC30

2000 Honda VTR1000 SP1

2000 Kawasaki ZX-7R

Re: Why I don't like [what gets done to] the Rover K series

sorry i know this is a bit random and off topic , but i have noticed that with the 2zz-ge and this engine…they like to design the cylinders nice and close together, to save space and hence a smaller block, im guessing....KingK_series wrote:Examples -

- below is a very expensive short end built but a "professional" who considered cracking liners were caused by the open topped block. In fact liners crack because the same company had continued to use the old plastic dowels, so apart from the misguided diagnosis these people decided to close the top of the block [not a bad idea in itself - that will have several advantages] by welding it up and re-machining it.

- There lies the problem, they were careless/ill informed/just didn't care to study the engine, enough to not realise that the K unlike all other production I4s is as light as it is BECAUSE of the use of a heat treated alloy LM25, and therefore by heating it enough to weld in the inserts the very remedy they were using was destroying the treated state of the block and rendering it scrap

On this newly rebuilt short end the builder's welding had reduced the hardness of the block from 120 brinnel to 42

Unknowing incompetence....

.but the draw back i can see is that there is no gap for coolant to be able to …well…cool. Surly that would result in a hot spot between the two cylinders???. also, the distance between is small and the amount of gasket material small as well... giving rise to a potential weak spot and lack of gasket material...and failure zone...the gasket has to now handle the extra heat and lack of material space.

not a great design in that reflection IMHO....

captian james t kirk-i am sorry i cant hear you, over the sound of how awesome i am-

1998 Audi Elige s1-1.8t 20v

05 Exige S2 - stage 2- Piperx VIS induction

1998 Audi Elige s1-1.8t 20v

05 Exige S2 - stage 2- Piperx VIS induction