Just an update on this thread

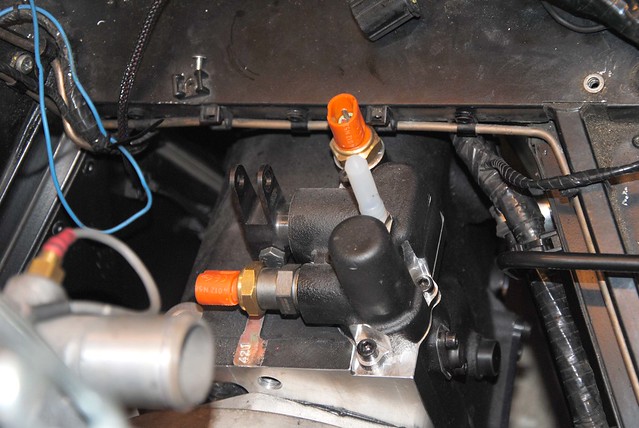

The engine had been extremely reliable last year, so this year I was tempted to play around with thinner oil grades to see if any power was on offer. Certainly there was more power, but one event saw oil temperatures getting rather elevated. I got the feeling that perhaps I’d pushed my luck too far.

The oil filter check confirmed a higher particle count than normal, but returning to a thicker oil for the final event of the year seemed to settle it down. But I knew a rebuild was on the cards, if nothing else, to give me peace of mind.

To give some perspective to what follows, the engine has completed 13 sprint events, and a similar number of trackdays, 6 rolling road sessions, 120 hours on the ECU, and about 1000 miles on the speedo. Reving to 8600, and producing up to 270 BHP

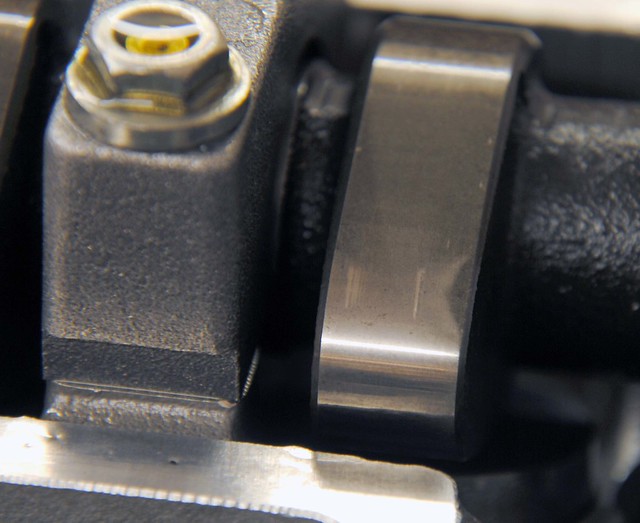

First impressions, when opening the cam cover, was that it all looked rather nice. The spark plugs were text book (if anything getting a bit hot) and the only thing that caught my eye was two small scores on one cam lobe.

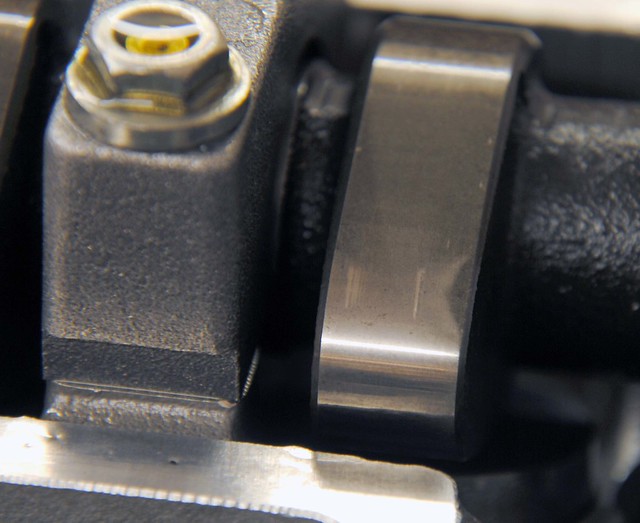

In hindsight, the two little scores where a clue to a more serious problem. And yes, the bearing next to that lobe was in trouble.

There was noticeable wear on the cam bearing and the cap looked a bit distressed too. Luckily the unloaded side (the head itself) seemed not to have suffered to the same degree.

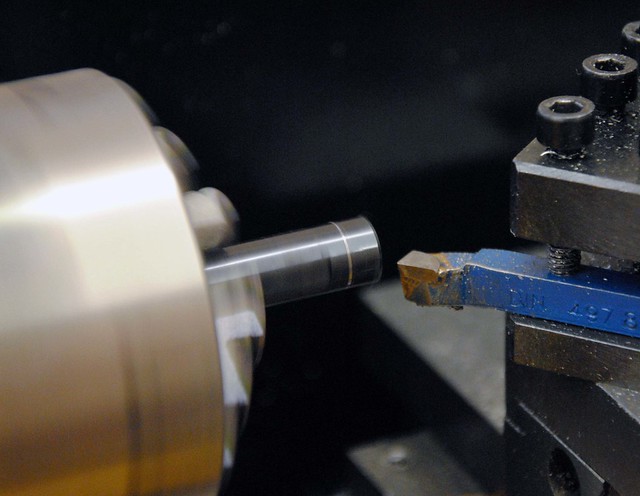

Now the cause of this is difficult to say for sure. The cam had two little hammer marks on the bearing surface which were within the oil groove most likely caused by it ingesting something via the oil.

But the bearing cap also looked porous, so maybe a problem there. Anyone’s guess to be honest.

One issue that played on my mind was the length of time this engine had been at idle. It has spent most of its time idling away, warming up, and waiting for sprint starts, so maybe low oil pressure played a part too - or at least assisted the failure.

I say failure, but it hadn’t failed really - the measured clearance was still within an acceptable limit, but it was not what you want on your race engine. The jury is out on the fix, but I will give it some thought, and probably look at the rest of the engine first.

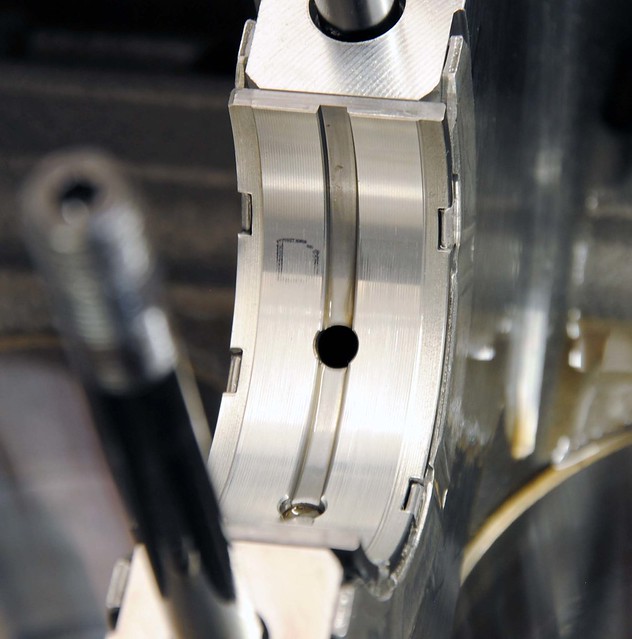

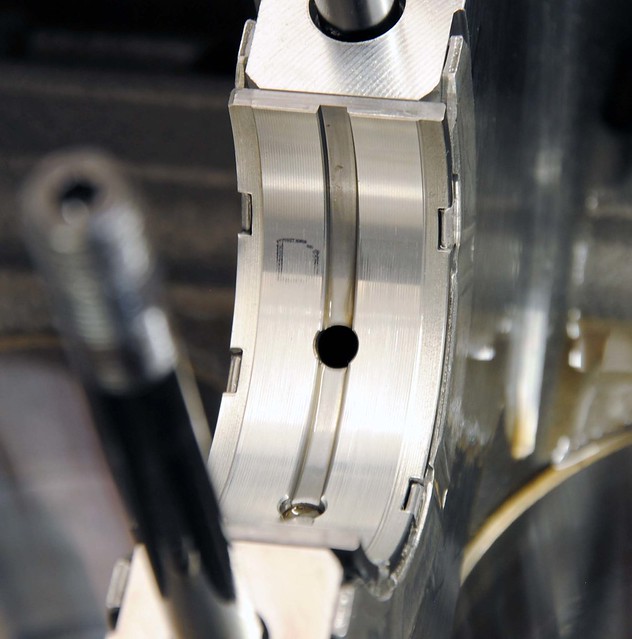

Moving on to the bottom end, things looked much as expected at first. Big end 1,2, & 3 where all running normally. But number 4 had clearly picked up something and was showing signs of distress and failure was not too far away.

Particles were causing little dents and disturbing the wear pattern. Speaking to various suppliers, it seems the VP2 tri metal bearings are designed to behave like this - absorbing any foreign matter (out of harm’s way) and buying you some extra time.

Having looked at many Duratec big end bearings now, I would recommend regular replacements if you are using high RPM on a frequent basis.

The mains looked like a totally different engine: the printing still present and not signs of wear whatsoever. That was a big relief as they are the one item that is difficult to replace due to the numerous grades.

All the journals should be serviceable after a polish, certainly not at a regrind stage yet.

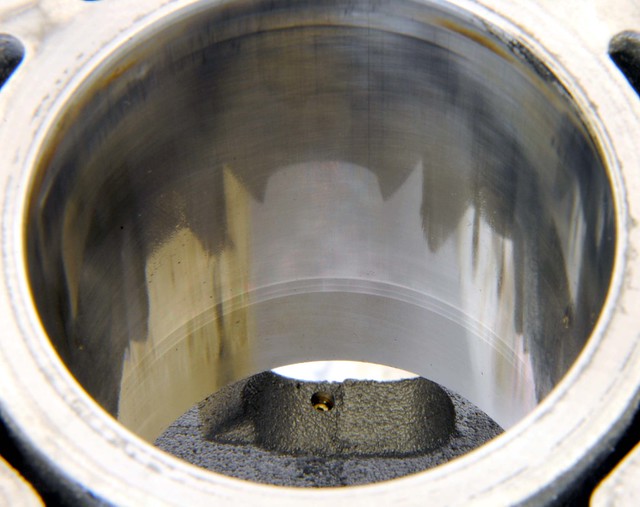

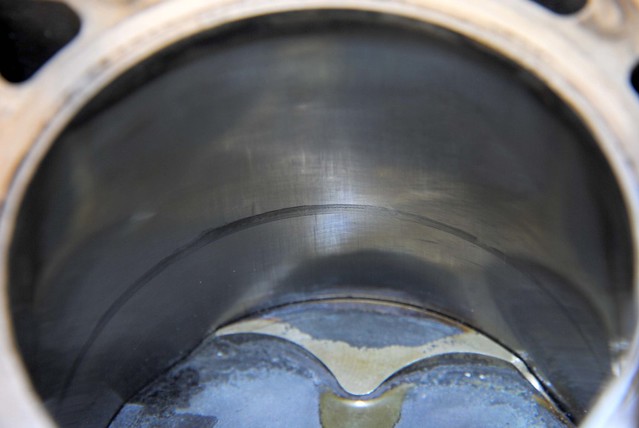

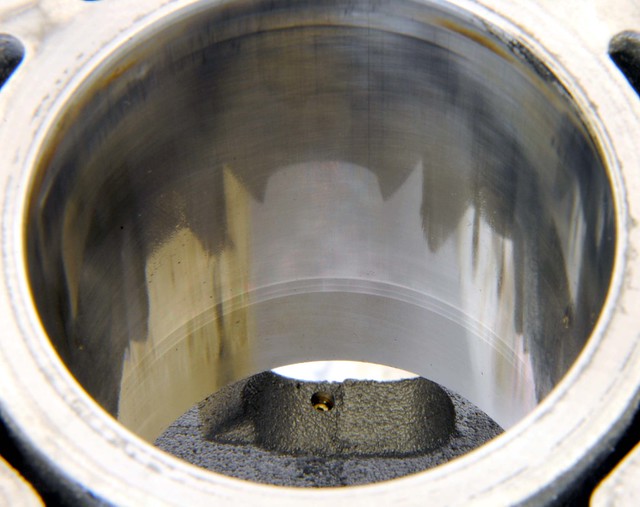

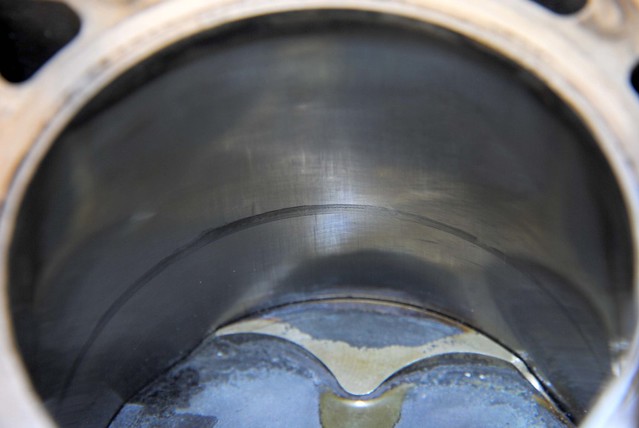

I was curious about the cylinder bores as this was the first engine I've run-in solely on the dyno. The initial results were outstanding on leak-down and BHP. But the second season did seem to take its toll and the last check suggested it had lost a little.

Clearly the bores have done some work, but I can't detect any measurable wear and all the ring gaps are the same as recorded in the build. There's no hint of any bore wash, and the honing marks are still visible, even through the heaviest of wear (more on that later). I'll give some thought as to whether to just lightly de-glaze the bores and rings, or do a full hone and replace the rings.

One unexpected surprise in cylinder 3 bore was a corrosion ring. The car is stored in the dry, and run on a regular basis so I was initially puzzled by it.

But thinking back, there was one occasion that I put the car to bed with a wet filter (it's a foam one). I guess the cylinder with the inlet valve open must have drawn in moist air as the engine cooled. It looks worse than it is, so hopefully it will come out with the de-glaze, or light hone.

But be warned if you have a foam filter - remove it from the air-box if it is wet!

There's not an awful lot to say about the Supertech pistons and Cosworth rods. They all came out with hardly a mark on them, just a hint of slap on the top edge.

But it's clear combustion temperatures were high as they were self cleaning around the exhaust valves. There's no alternative to forged pistons at this level of tune.

Duratecs don't have a reputation for cylinder head gasket problems, so I fitted the standard gasket on this engine. However, on close inspection, there's some evidence of movement and wear.

I think it would be fair to say that the standard gasket will do the job, but it probably has a limited lifespan at these sort of power levels.

Those with a good memory may recall the burr embedded in a cam bearing. When it was removed, it left a sizeable hole. Well, there seems to have been some healing going on, and it looks better now.

This is something I've noticed on aluminium bearings before - they seem to improve with age. The Bearing material seems able to move around to fill the imperfections.

The dismantling of the head concluded the strip-down. I'm pleased to say there were no problems with the valves or followers - nothing more than a light lapping of the valve seats and a clean and polish will be needed.

So what's the conclusion?

I Think I should have done it a year earlier! There's no doubt that once you go to 260+ BHP, the life reduces. At a guess, this engine is wearing out about 10 times faster than a road car engine. Possibly I encouraged the bearing issue with the thinner oil. This does release more power, but ALL your bearings do need to be in perfect condition. Probably something only for the race teams with big budgets, and plenty of spare engines.

The Duratec can be reliable at this state of tune, if not immune, from problems. But I would strongly recommend a seasonal rebuild/check/refresh if you are racing.