The place to "speak geek"

-

robin

- Jedi Master

- Posts: 10544

- Joined: Mon Mar 27, 2006 1:39 pm

Post

by robin » Fri Aug 14, 2015 5:15 pm

Tut's memory is more selective

I wouldn't use the MSPB to adjust fuelling for the MOT test cells - because it will change fuelling everywhere - and if you lean it out, that might very bad for the engine in the upper load/speed sites.

Given that the idle sites are at closed throttle, there is very little damage you can really do here - so if you're going to do anything, I would wind the fuelling down on just these sites - using the trim in the live settings page to work out a reasonable setting and then commit that cell to the fuelling table. Then take it to Emerald

Cheers,

Robin

I is in your loomz nibblin ur wirez

#bemoretut

-

Ferg

- Posts: 3966

- Joined: Fri Sep 04, 2009 11:56 pm

- Location: Auld Reekie

Post

by Ferg » Thu Aug 20, 2015 10:55 pm

Thanks for all the info so far.

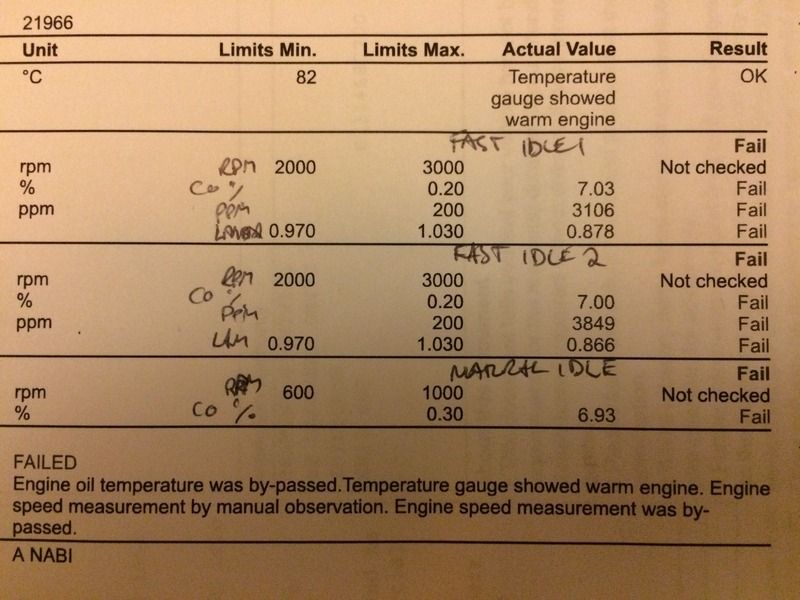

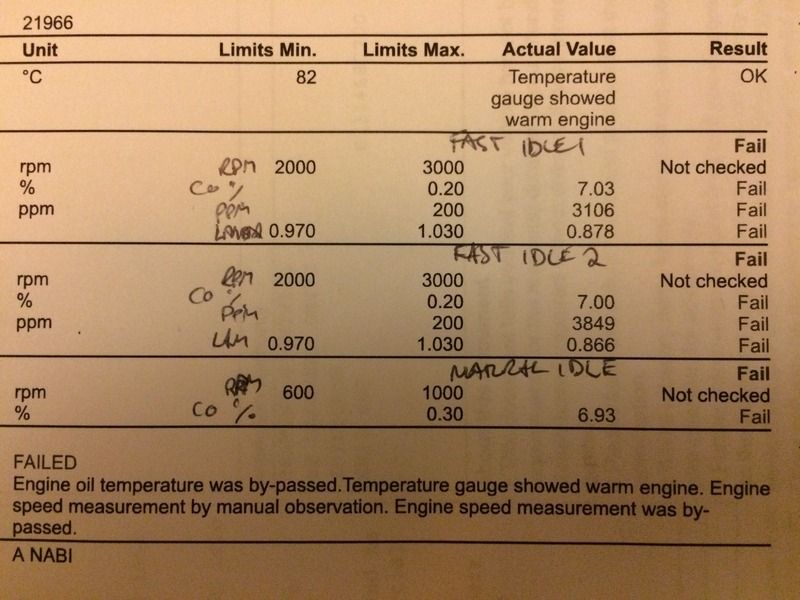

Here's the emissions fail sheet to show how badly it failed.

I'm going to reduce the fueling as configured just now, but have also just received this for getting it sorted properly after MOT complete.

Actually getting some time this weekend to look at the car, will report on progress.

-

steve_weegie

- Posts: 3248

- Joined: Tue Jun 28, 2005 12:40 am

- Location: Nessieland

Post

by steve_weegie » Fri Aug 21, 2015 12:23 am

Given an accurate enough map, you can fly an aircraft with no windows through the alps.

Your map is borked

The wideband is your window

I'd fit that first, personally speaking

Arriving broadside, in a cloud of smoke......

-

Mikie711

- Posts: 4344

- Joined: Mon Sep 10, 2007 11:21 pm

- Location: Aberdeenshire.

-

Contact:

Post

by Mikie711 » Fri Aug 21, 2015 9:46 am

steve_weegie wrote:Given an accurate enough map, you can fly an aircraft with no windows through the alps.

Your map is borked

The wideband is your window

I'd fit that first, personally speaking

Elise S2 260

BMW M2 Comp

RRS HST

BMW R1300GS

-

2F45T4U

- Posts: 312

- Joined: Wed Nov 21, 2007 10:35 am

- Location: Aberdeenshire

Post

by 2F45T4U » Fri Aug 21, 2015 5:24 pm

Yup. No point in doing anything til that wideband's fitted and working.

-

Ferg

- Posts: 3966

- Joined: Fri Sep 04, 2009 11:56 pm

- Location: Auld Reekie

Post

by Ferg » Sat Aug 22, 2015 3:06 pm

I think the writing is on the wall on that front

thanks guys.

-

Ferg

- Posts: 3966

- Joined: Fri Sep 04, 2009 11:56 pm

- Location: Auld Reekie

Post

by Ferg » Mon Aug 24, 2015 4:17 pm

Easy bit done a in the sensor is in and run to the bulkhead. Just waiting on some ecu pins from Emerald (what a nice helpful bunch they are) so I can hook into the ECU plug.

Learning loads as I go;

- Two of the spare inputs are already used, one for MAP sensor the other I'v not quite worked out. Neither are being used in the config but means I have less inputs to work with.

- I don't know if I'm more surprised or disappointed by the concept of grouped injection. For some reason I had assumed that they would be fired sequentially. I had to read it in a number of locations before I believed it was a standard approach.

-

2F45T4U

- Posts: 312

- Joined: Wed Nov 21, 2007 10:35 am

- Location: Aberdeenshire

Post

by 2F45T4U » Mon Aug 24, 2015 4:33 pm

There are arguments for and against batched/group. Its great for flowing more out of std injectors, but worse for emissions and fuel consumption as well as loss of individual trim.

-

robin

- Jedi Master

- Posts: 10544

- Joined: Mon Mar 27, 2006 1:39 pm

Post

by robin » Mon Aug 24, 2015 6:17 pm

It's normal for K series engines to run batched (i.e. run them in two pairs). The EU3 engine went to fully sequential injection, but only for emissions reasons, I think. Remember, the old carburettor worked well enough ....

Cheers,

Robin

I is in your loomz nibblin ur wirez

#bemoretut

-

Ferg

- Posts: 3966

- Joined: Fri Sep 04, 2009 11:56 pm

- Location: Auld Reekie

Post

by Ferg » Mon Aug 24, 2015 6:27 pm

I suppose it was the idea that there is stagnant (even though very briefly) air-fuel mix in the inlet. Then though the idea that at full chat the injectors are basically open all the time just points to how fast everything is happening. Going further down the rabbit hole day by day ...

-

2F45T4U

- Posts: 312

- Joined: Wed Nov 21, 2007 10:35 am

- Location: Aberdeenshire

Post

by 2F45T4U » Mon Aug 24, 2015 6:47 pm

ye, pretty much.

on sequential the squirt is timed/phased with the inlet valve being open (each one squirts individualy as per the firing order). The problem is you get less time to squirt the fuel you want in this now much shorter opportunity, but unlike batch the squirt isnt sitting around behind the closed valve until it opens again. But you now have 4 (or 1x no. of cylinders) opportunity to add the fuel per cycle, duty cycle decreases and you 'could' use smaller injectors

You have to be pretty much looking for the ends of a fart for it to make much difference providing each one is properly mapped. Ive done both. Using batch temporarily on turbo conversions rather than increasing the fuel pressure, or if there is no cam/sync pulse fitted and its not possible to have sequential. Playing with the phasing of sequential takes hours and probably wastes more fuel during mapping than you would by driving a few k miles a year in batch... at the moment MOT emissions are only tested at 2 points anyway which is perfectly achievable in batch.

batching the groups is a halfway house between the two but still needs a cam trigger or sync pulse.

-

robin

- Jedi Master

- Posts: 10544

- Joined: Mon Mar 27, 2006 1:39 pm

Post

by robin » Mon Aug 24, 2015 7:33 pm

Batching can be done without a cam pulse. You fire each injector twice for half the total duration. E.g. fire #1 & #4 at TDC, fire #2 and #3 at BDC. That way you get one half-squirt onto a closed inlet valve and one half squirt onto an opening inlet valve.

Cheers,

Robin

I is in your loomz nibblin ur wirez

#bemoretut

-

2F45T4U

- Posts: 312

- Joined: Wed Nov 21, 2007 10:35 am

- Location: Aberdeenshire

Post

by 2F45T4U » Mon Aug 24, 2015 7:46 pm

Ye thats a point actually, providing you had a lost tooth on the crank trigger to start the count, that would work.

-

robin

- Jedi Master

- Posts: 10544

- Joined: Mon Mar 27, 2006 1:39 pm

Post

by robin » Mon Aug 24, 2015 8:29 pm

If you don't know what the crank angle is, good luck doing ignition timing

Of course on ancient engines you would use the distributor ... but on any engine built in the last 20 years you should have electronic ignition of some type.

I is in your loomz nibblin ur wirez

#bemoretut

-

2F45T4U

- Posts: 312

- Joined: Wed Nov 21, 2007 10:35 am

- Location: Aberdeenshire

Post

by 2F45T4U » Mon Aug 24, 2015 9:05 pm

robin wrote:If you don't know what the crank angle is, good luck doing ignition timing

obviously, but what i said isnt necessarily stupid either.. all you need to know the angle is a ref pulse per cylinder + a known known angle for the pickup to give a trigger reference to run a basic batch fire and distributor setup on something such as an early K with full control over spark.

robin wrote:Of course on ancient engines you would use the distributor ...

mechanical spark timing yes of old engines yes, but as you know even relatively modern engines relied on distributors purely for physical distribution of spark (such as the MPI K series).

which needs either:

a ref tooth on the crank wheel or no ref tooth and a sync pulse on the cam to know where TDC of no.1 is

or

no crank sensor, a cam pick-up and a distributor.

(as a minimum)