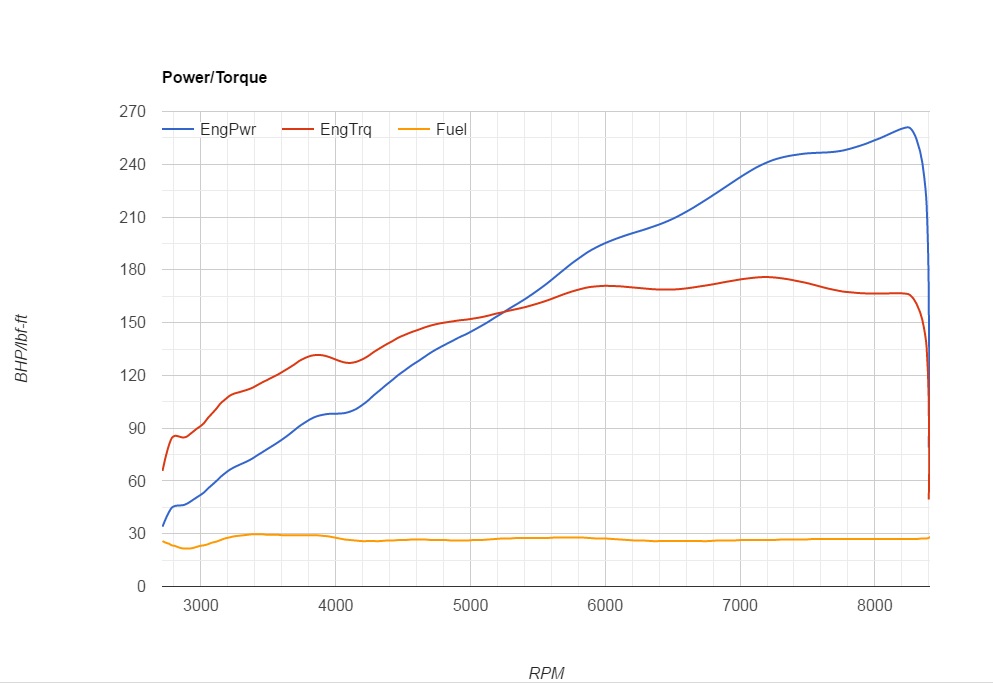

This year I really felt this project had peaked. Not because there wasn’t more performance available from the 2L Duratec, but because I had become aware how much stress a 2L 8500+ rpm engine was under. Three seasons was asking a lot - it was time to retire the engine to the spares corner in the garage.

Last year I had commissioned a new head with the intention of building a new zero hour engine for 2017, and that arrived a couple of day before the SLS final. Perhaps that was tempting fate, but the engine must have known its time was up . . . and it didn't want to go quietly.

Picture courtesy of Richard Breakell

During the first hot lap in qualifying, I noticed a misfire going up Duffus (reverse direction). In hindsight, I should have abandoned the session at that point, but, with oil pressure and temps normal, I was keen to get a lap time. The misfire cleared for a while, but returned on the back straight and developed into a mechanical rattle as I approached the chicane. The throttle then would not close and the revving engine spectacularly ground itself to bits in a big cloud of smoke. I finally shut it down as I coasted to halt. I knew it was bad, but I was more upset about not finishing the event - my first time ever in the SLS.

Watch on YouTube

There was a fist size hole in the crank, but I sensed this was not a big end failure. The engine was rotating so freely, and with oil pressure normal throughout, it had to be a dropped valve, and that probably meant a valve spring failure.

Once home, this was was quickly confirmed . . .

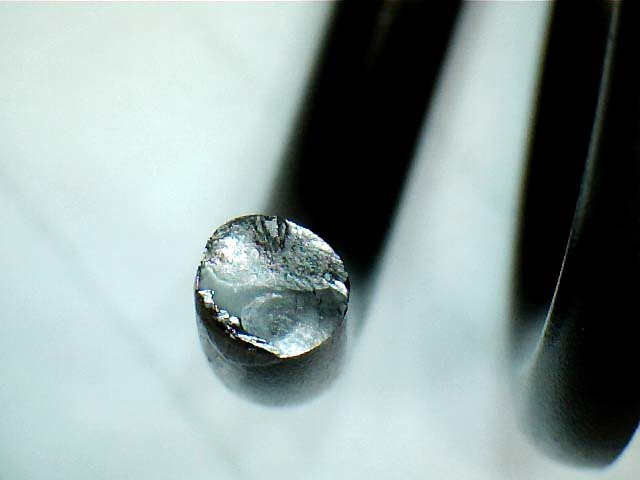

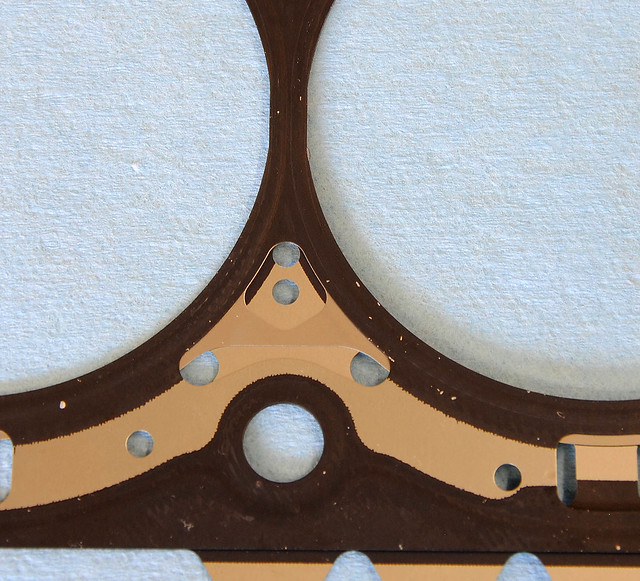

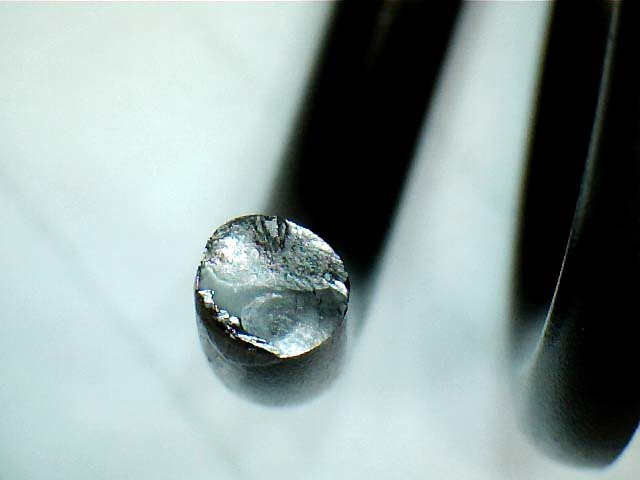

The spring showing a classic fatigue fracture . . .

It had logged 85 hours, all on track. That is on the lower end of what you might expect from a spring, but not outside the life expectancy with the cam lift and and RPM I was using. Kent Cams have offered to analyse the spring and I will take them up on that offer, but they initial response is that it was not a combination of cam profile they have tested. They say the spring was intended to be used as a duplex set. Strangely they supply seats and retainers to use it as single spring. The early R500 Duratecs do have a history of valve spring failures, but this one is a different spring. Personally, I suspect resonance played a part in the failure as the position of the break strongly suggest that.

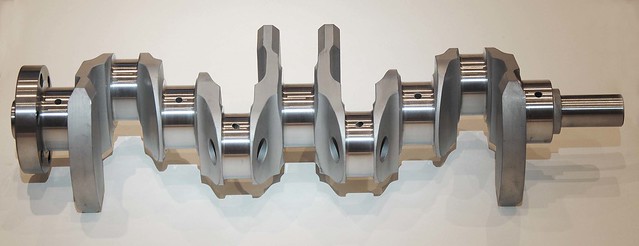

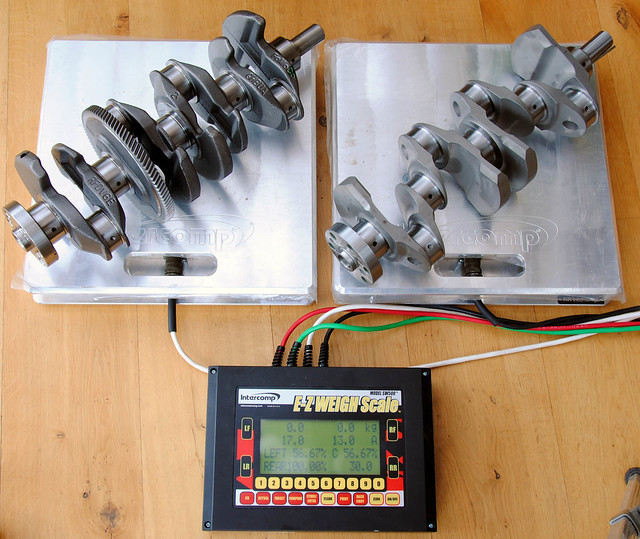

The rest of the engine was essentially a write off, and I don’t intend to reuse any of the stressed parts in my new engine, but I’d be happy to run the crank, cams, drysump, remaining rods, pistons, valves, cams, in a ‘down rated’ engine.

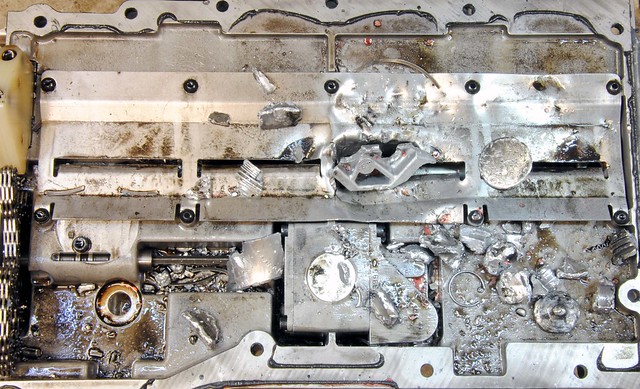

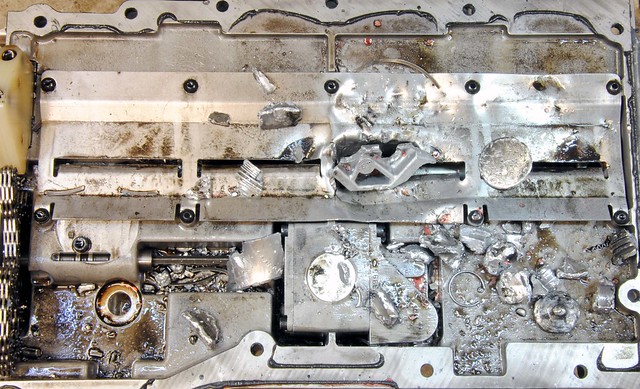

For your entertainment, here’s some photos of the carnage . . .

The dry sump damage to the windage tray, but otherwise intact

The gudgeon pin circlip that jammed the throttle open.

So what’s for next year?

As said, I’ve already got a new head, this time to an even higher spec (bigger valves and seats) with hotter cams - basically as far as you can go with the standard head. But what it will be matted with is still under wraps

But it is looking like something a little bespoke. I’ll keep you posted.