With this engine (and it's extremely long stroke) I decided it was worth going to the extra effort of balancing it professionally.

So it was off to Midland Balancing Ltd to spend an interesting few hours in their workshop. It is in part of a working farm and not the place you'd expect find McLaren cranks by the dozen, nor the precision grinding of racing cranks for BTCC cars, but their reputation for quality work didn't seem to be affected by farming environment.

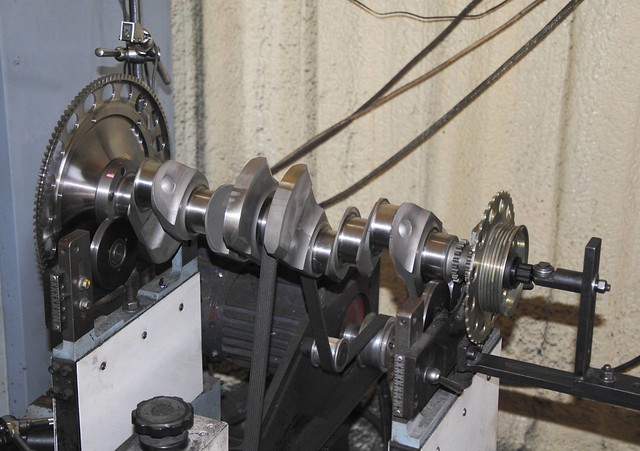

Spinning up my crank on their balance rig was straightforward with no bob weights required on an inline 4 cylinder. It proved to be good out the box at 5 grams at 1 cm (less than 0.5 grams at the web), that was good figure! Even more satisfying was that it appeared to be the key-way that was causing the unbalance, and when we fitted the sprocket and pulley it got better. After some light grinding we got it down to 2-3 grams at 1 cm (about as low as we could measure reliably). Then the flywheel was fitted and a small adjustment made to bring it back to same balance.

Following that, the pistons rods, and pins where weighed and mixed and matched to find the best balance. In the end we achieved 0.1 gram between the set without removing material - a truly remarkable figure and praise should go to Omega and Robson for there ability to provide such good matching sets.

Finally we used a rig with precision bearings to measure each end of the rods. All were within 0.5 grams and we felt that it was better to maintain the peened finish than adjust.

This is probably the best balanced set of parts I have ever achieved. Whether that is luck, or just everyone upping their game for this 'early' spec engine, I don't know.

|

| |

| |

|